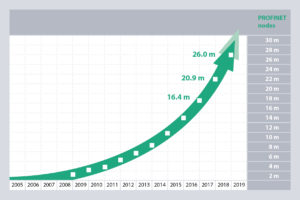

PROFIBUS and PROFINET International (PI) celebrated its 30th birthday in 2019 with 1,700 member companies worldwide working together to make the best automation technology for industrial networking. Worldwide, the PROFINET and PROFIBUS node count topped 87 million in the year 2018, out of which PROFINET continues its accelerated growth and reached 26 million devices in total and 5.1 million new devices being added.

PROFIBUS and PROFINET International (PI) celebrated its 30th birthday in 2019 with 1,700 member companies worldwide working together to make the best automation technology for industrial networking. Worldwide, the PROFINET and PROFIBUS node count topped 87 million in the year 2018, out of which PROFINET continues its accelerated growth and reached 26 million devices in total and 5.1 million new devices being added.

On the other hand, OPC UA has become the de facto global standard for exchanging the information reliably and securely between the automation systems. There are 47 million automation devices containing OPC technology as per an ARC Advisory Group report published in 2018. It is also anticipated that OPC usage will grow at approximately 45% annually for the next 5 years.

Even though PROFINET and OPC UA have some overlap in the automation and process industries, they complement each other very well in bringing the best vertical and horizontal integration possible.

From Data to Valuable Insight

In a typical automation topology, as shown below, at the field level and up to controller level, PROFINET shall be used for the exchange of cyclic and real-time capable I/O data.

OPC UA in PROFINET Controller/PLC or Edge Gateway

OPC UA in PROFINET Controller/PLC or Edge Gateway

OPC UA can be integrated into the edge device, in this case, a PROFINET Controller or PLC. In this scenario I/O data fetched from multiple PROFINET I/O devices are aggregated and analyzed, turning the raw I/O data into the valuable information. This enables the vertical integration of the field device data into the high-level enterprise-level application. Also, if multiple controllers are OPC UA enabled, then horizontal communication between controllers can be achieved.

If the existing PLC does not have support for OPC UA, then external edge gateways can be used as an alternative. In this way, data can be fetched and turned into valuable information without disturbing the existing process. This is one of the principles behind the NAMUR Open Architecture (NOA).

OPC UA in a PROFINET device

OPC UA can be integrated into PROFINET devices to share asset management and diagnostic information with higher-level systems. This can be useful in scenarios where a PROFINET device is not configured to share relevant asset and diagnostic information with its I/O Controller, or the frequency of the data collected by this device is much higher than the controller scan cycle rate. In this scenario, the PROFINET device may have a local PROFINET / OPC UA Information Model. Since both PROFINET and OPC UA share a common Ethernet network, they can share the same infrastructure. However, as there is the possibility of OPC UA consuming most of the network bandwidth, care should be taken to ensure that this does not affect the performance of PROFINET packets. This can be handled by making network TSN enabled.

Conclusions

- PROFINET and OPC UA together makes horizontal and vertical integration efficient, by turning the raw data from field devices into valuable information as expected by higher-level decision-making systems.

- OPC UA can be integrated into a PROFINET device, PROFINET Controller (e.g. DCS, PLC) or edge gateway.

- PROFINET and OPC UA in edge gateways enable use-cases like the NAMUR Open Architecture (NOA) which focuses on monitoring and optimizing process information without disturbing an existing system, instead, adding an additional secure OPC UA channel.

Authors: Sivansethu G, Smitha Rao – Utthunga Technologies