In this article we will cover the details of PROFINET diagnostic concepts and use-cases covered by the PROFINET and OPC UA Companion Specification for mapping diagnostic information from a PROFINET device to OPC UA.

Below are six use cases supported currently by mapping PROFINET diagnostic information to OPC UA:

- Identify if there is any difference between the expected configuration in the engineering system of the I/O Controller versus what is actually installed on the device

- List the installed devices and their configurations in the field

- Current state of the PROFINET connection related to the expected configuration

- Differences between the expected and real configuration related to modules/submodules, their identification information, and reasons for any connection problems

- Diagnostic or maintenance update related information of the device/module/submodule/channel

- Information about the “health” of the physical PROFINET network in a diagnostic tool with a topological view

PROFINET Diagnostics: Technical Know-How

Device and network diagnostics are crucial for the proper functioning of a plant. PROFINET defines a comprehensive diagnostic model.

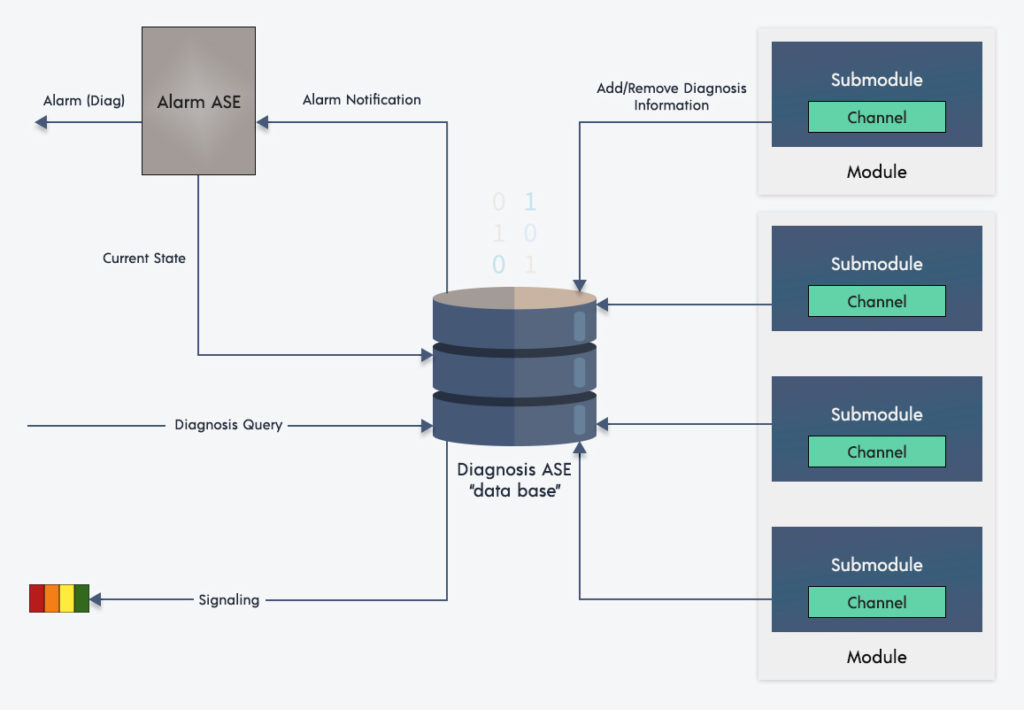

Each PROFINET device maintains a Diagnosis ASE, which is nothing but the repository of the global list of active diagnostics from a channel. A ‘channel’ in this scenario can be a connected sensor, or an entire submodule. When there is a diagnostic that appears in the channel, it will be updated with the Diagnosis ASE repository. Each channel diagnostic entry contains a severity (Fault / Maintenance Demanded / Maintenance required / Good –from high to low) and error codes. When there is a query from some upper supervisory system (e.g. edge gateway), relevant diagnostic information will be shared.

High-Level Architecture of PROFINET Diagnostics

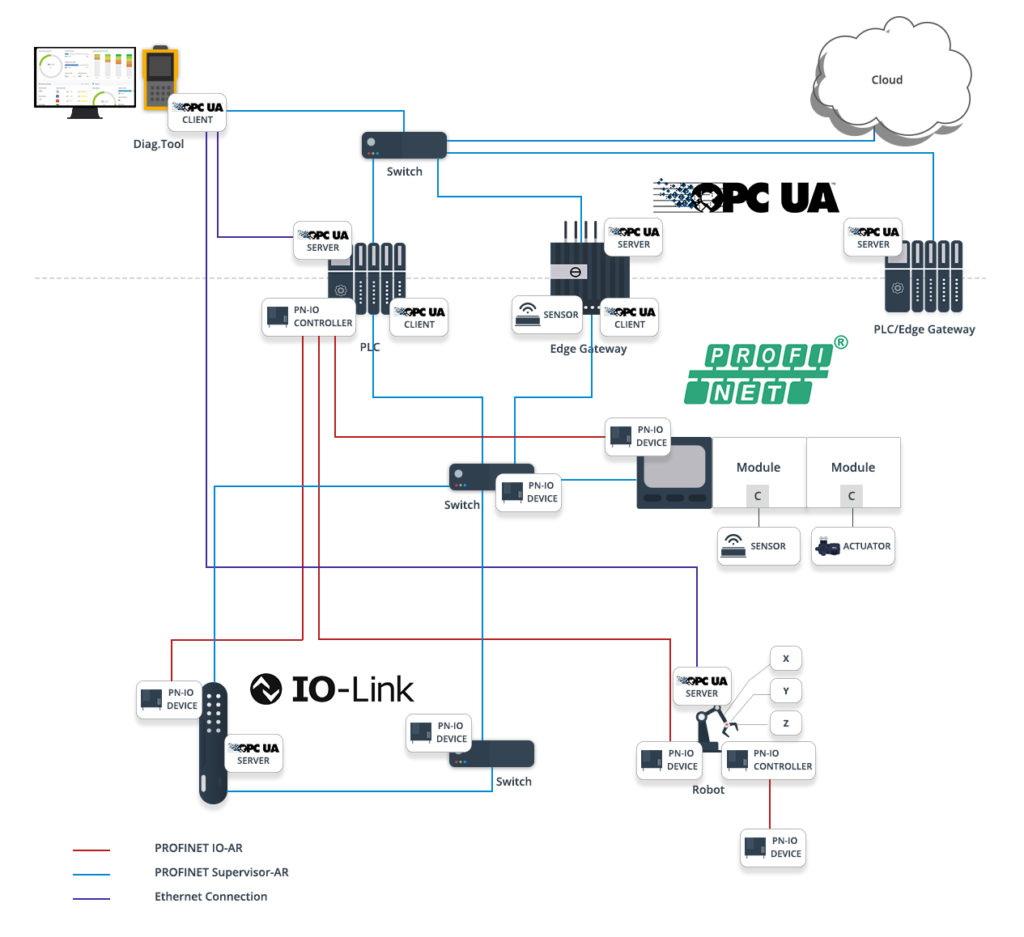

In a typical automation scenario, a diagnostic tool is connected to the PLC, edge gateway, or PROFNET device with built-in OPC UA capability. As shown in the below architecture diagram, the diagnostic information provided by the I/O Controller device will be different from the edge gateway. For instance, if the PROFINET device is unreachable from the edge gateway during its scanning process, the reason for this can be different compared to the PROFINET Controller point of view.

Conclusion

Mapping PROFINET diagnostics to OPC UA will enable higher-level systems to make informed decisions resulting in lower downtime, increasing the overall efficiency of the asset.

Authors: Sivansethu G, Smitha Rao – Utthunga Technologies