omlox, the Industrial Location Standard, Takes Off

In the past, not much value was placed on the localization of equipment, load carriers, or tools in production. Existing solutions were too imprecise, too expensive, or not reliable. Now a new day is dawning with the omlox industrial location standard. It can not only be used to locate a work-piece exactly but also to redesign processes at the company and make them more efficient.

If you compare the consumer sector to the industry sector with regard to location data, what stands out, in particular, is the speed. The consumer industry is driving all participants ahead at high speed. This is surely due also to the fact that this industry consists of just a few global players. However, that’s not the crucial difference: In the consumer sector, people don’t actually know precisely who has access to the data. The situation is completely different in industry/logistics. Here, people are more vigilant, and data protection is critical.

However, this is just one of the reasons why the handling of location data has not yet made a breakthrough in the industry, while it is already a matter of course in the private sector. There is also mobile data exchange in industry, for example, when WiFi, Bluetooth, or AGVs (autonomous guided vehicles) are being used. But there is not yet any uniform standard in this industry. In addition, these technologies frequently struggle with imprecise location, high energy consumption, or lack of interoperability. The current solutions are also expensive and are hardly transferable to other applications. Frequently it even happens that a tag works in Hall 1, but not in Hall 2. The result is that the market is fragmented and isolated solutions are part of everyday life.

Location Indoors Has a Lot of Potential

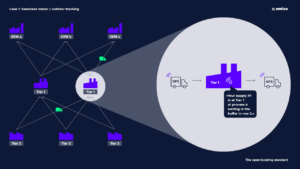

In recent years, there was a lot of excitement about digitalization through Industry 4.0 applications. But many such ideas can only be realized if there are affordable solutions. Load carriers, work-piece carriers, etc., are frequently regarded per piece; they are not especially valuable assets, but together they add up. There are estimates that the potential for data exchange just in the production area amounts to $100 billion.

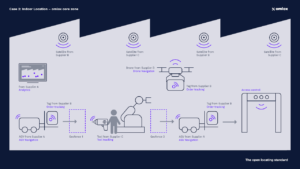

The new open mobile omlox location standard aims to fill precisely this gap, which will ease logistics and increase security at companies. In addition to asset tracking, there is a multitude of other applications where precise location will improve processes indoors. These include anti-collision strategies, safety applications, access controls in warehouses and production, navigation, and other automatic actions.

Strong Partnership

Omlox was created by more than 60 companies. Since it is an open standard, any company can develop omlox-compatible products. In contrast to the consumer industry, with omlox, the plant manager has control over the data. Meanwhile, the location standard version 1.0 is available; the first omlox-capable software and hardware solutions from participating companies have already been presented.

Since last year, PROFIBUS & PROFINET International (PI) has hosted this technology so that it will find its way into practice quickly. Benefits arise, for example, from the use of established globally networked structures and from a proven set of rules for committees’ work; the handling of patents and copyrights; as well as the use of the regional PI associations’ existing contacts, competence centers, and training centers for the regions’ industrial companies. Here the omlox technology – like IO-Link – is technologically independent from PROFIBUS and PROFINET. Thus, users can rely on the fact that products with the omlox label have passed an interoperability test, similar to how this works with other PI products.

How Does omlox Work?

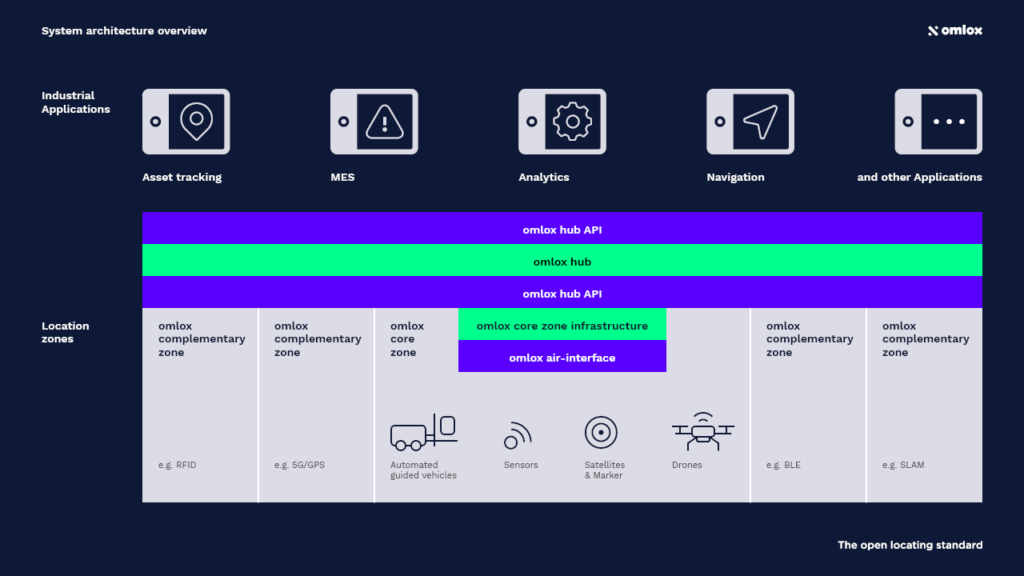

The omlox core zone guarantees interoperability in the ultra-wideband (UWB) range. This is a close-range radio standard that is used for indoor localization in factories. Ultra-wideband is especially robust and guarantees a stable connection – even if there are obstacles and despite metallic reflections. The omlox core zone provides the infrastructure for integrating various hardware products such as AGVs and sensors from a wide variety of manufacturers. The omlox core zone is analogous to network at your home, which easily connects mobile phones, PCs, printers, TVs, etc. – thanks to the WIFI standard!

Another central element is the omlox hub – this software connects other localization technologies, e.g., between technologies inside the building (such as UWB solutions, but also RFID, 5G, Bluetooth) with solutions outdoors (e.g., GPS). The omlox hub integrates all location-related data, puts it in a uniform coordinate system, and that means that the overlaid software only has to be developed once. The “islands” are resolved via the hub and can then even be localized on Google Maps.

This enables users to adjust their location solutions completely without regard to the manufacturer. Every mobile omlox device can be located in the omlox infrastructure by any manufacturer. The same applies to the omlox hub and other location applications that comply with omlox specifications. Standardized interfaces ensure interoperability between the individual layers.

In practice, the omlox tag is simply affixed to the carrier or integrated directly. A cloud location service keeps the supply chain manager up-to-date with the status of his deliveries outside and inside – in real-time. Even auxiliary products in the supply chain can be traced, which enables better recycling rates and increased efficiency, and at the same time, supports sustainable global economic activity.

Outlook

In the first step, omlox will concentrate on asset management and its optimization; a little later, the incorporation of autonomous objects should follow. Later still, the focus will be on navigation, information, and content for augmented reality. Finally, tasks with regard to safety, such as for Cobots and anti-collision strategies, should follow.

Even today, the first applications demonstrate that real-time tracking of objects in the course of production can produce significant savings. The object has a “digital shadow,” and this entirely without extra work. This makes many bookings, material request reports, and the creation of transport orders within the production process obsolete since this information “runs along” with the work-piece or object automatically. This saves time, work, and minimizes defects.

Many AGV-related tasks will no longer be necessary, thanks to omlox. These include set-up and training runs, opening doors and rolling gates, adjusting lift truck speed, and starting and ending loading processes. Omlox that is integrated into AGVs, drones, etc., can perform all of these tasks.

Still a future dream, but already tried out in development was incorporating omlox into AR goggles. Hardly will a service technician have arrived on a company’s unfamiliar premises when he will be led to the right machine, the one he is supposed to repair. Omlox will show him the way.

Eberhard Wahl

Eberhard Wahl

Head, New Business Technology at Trumpf

Head, omlox Use Cases WG at PI

How much effort does it take to use the technology?

In purchasing, the user has to pay attention to the omlox compatibility of his equipment. Of course, the current selection is still expanding, and not everything already available is omlox-compatible, but demand will generate additional offerings here. The infrastructure can be realized, for example, in that in the future, lighting will be acquired with omlox already incorporated into it. Similarly, all mobile objects, from rechargeable screwdrivers to AGVs, can be equipped with omlox at the factory, and the software can be used easily, thanks to omlox compatibility.

Omlox has been on the market for six months already; what’s your preliminary assessment?

We already have a broad range of omlox solutions on the market (see https://omlox.com/product-classification ), and users are very interested in interoperability. Solutions for asset management are available, other applications are being tested. As with all standards, it will probably take a few years before the standard is widely available in many products. This is where we will need some time and support from users who require this openness from their suppliers.

What will be your next steps?

Currently, we are engaged in additional pilot projects in order to confirm the utility of omlox in many other applications. For this year, we are still seeking innovative early adopters who will serve as pilot users in order to advance this standard and incorporate their requirements into its further enhancement.