The Coexistence of IO-Link Wireless and 5G

Nowadays, wireless applications have become an indispensable part of our everyday lives. We get into the car in the morning and connect our cell phone wirelessly to the hands-free system. In the meeting room, the beamer is connected to the laptop via a Wi-Fi hotspot, and the telephone conference is conducted using a wireless headset. In the meantime, users are no longer concerned about how these wireless connections are established and whether they are stable. Only when the connection is interrupted due to a problem, do they take a closer look at this technology.

Wireless Technology in Industrial Automation

In industrial environments, however, wireless technology is met with much greater reservations, primarily because those responsible for production strive for the highest possible machine availability; machine downtimes are often associated with high costs. In contrast with a wired solution, however, machine communications cannot be physically tested, which means that a potential failure quickly becomes a challenge. Collisions of the packets with relevant information from other packets in the same frequency band, as well as shielding/reflection of the nodes by components in the immediate vicinity, can occur, for example. In both cases, this can result in a communication breakdown, in a control malfunction after just a few milliseconds, and ultimately in the shutdown of the plant. In the past, such problems were difficult to prevent using existing wireless technologies, which were often proprietary. This circumstance also greatly hindered the adoption of wireless components in industrial automation.

It is in precisely these situations, however, that the call for wireless applications is getting louder and louder. What is required here are industry standards that offer users the greatest possible flexibility, diversity, and scalability. Existing wireless networks cannot meet the requirements for reliability, device density, installation effort, and physical dimensions, so they are rarely used.

The New Wireless Generation

A recently published study with a representative survey of 50 international industry professionals by industrial communications technology manufacturer HMS Networks found that wireless applications for remote monitoring and remote control of equipment are already a reality today and are already being used by over 54% of the respondents to the study. 48% also claimed that they are positive about 5G and would like to use this technology instead of the unreliable Wi-Fi and its various industrial derivatives. In the context of 5G (Ultra Reliable and Low Latency Communication), however, another standardized wireless technology called IO-Link Wireless should also be mentioned. Both standards in coexistence create a great added value and potentiate each other’s respective areas of application.

IO-Link Wireless is a standard that was defined specifically for factory automation. It provides a reliable, real-time, and deterministic protocol for control systems in industrial factory automation. It adds wireless transmission links to the classic wired cables in industrial control applications, increasing mobility and flexibility and elevating plant communications to the master level of automation.

In parallel, companies are starting to market various 5G-based products and services as part of the fourth industrial revolution. In this context, the 5G transformation is designed to take several years, as production deployments require stable specifications, production-grade implementation, and supportive ecosystems before widespread availability can be achieved.

Wireless Implementation Considerations

If a wireless communication solution is to be implemented for a machine, several key factors must be taken into consideration:

- Output

- Latency

- Application

- Physical dimensions

- Range

- Costs

- Availability of the frequency spectrum

The table below compares the two industrial technologies: 5G (uRLLc) and IOLW. uRLLc (currently Release 16) has not yet been adopted as a generally applicable standard.

| Key factors | 5G (uRLLc) | IO-Link Wireless |

| Output | 5G offers a system PER (Packet Error Rate) of 10-5 | IO-Link Wireless offers a system PER (Packet Error Rate) of 10-9 (a factor of 3 more reliable than existing wireless networks) |

| Latency | The theoretical target of 1 ms at <10-5 error rate. (Not metrologically proven until now) | 5 ms at 10-9 error rate measured in existing systems |

| Application | Primarily designed for devices with Ethernet communication and high bandwidth. | Primarily designed for sensors and actuators with low process data length/bandwidth. |

| Physical dimensions | The physical dimensions of the chips have not yet been clearly defined. | The IO-Link wireless device components can be sized as small as 11 x 17 mm. |

| Range | 5G offers a range of 50 meters to 1 kilometer (depending on frequency band and cycle time) | IOLW provides a range of 10-20 meters between the master and device (global 2.4 GHz ISM band) |

| Costs | License costs for the frequency band and higher chip costs are foreseeable | License-free frequency band and chip costs in the low euro range |

| Availability of the frequency spectrum | The frequency spectrum is centrally organized and specifically allocated | The frequency spectrum is freely accessible |

Coexistence of Both Technologies

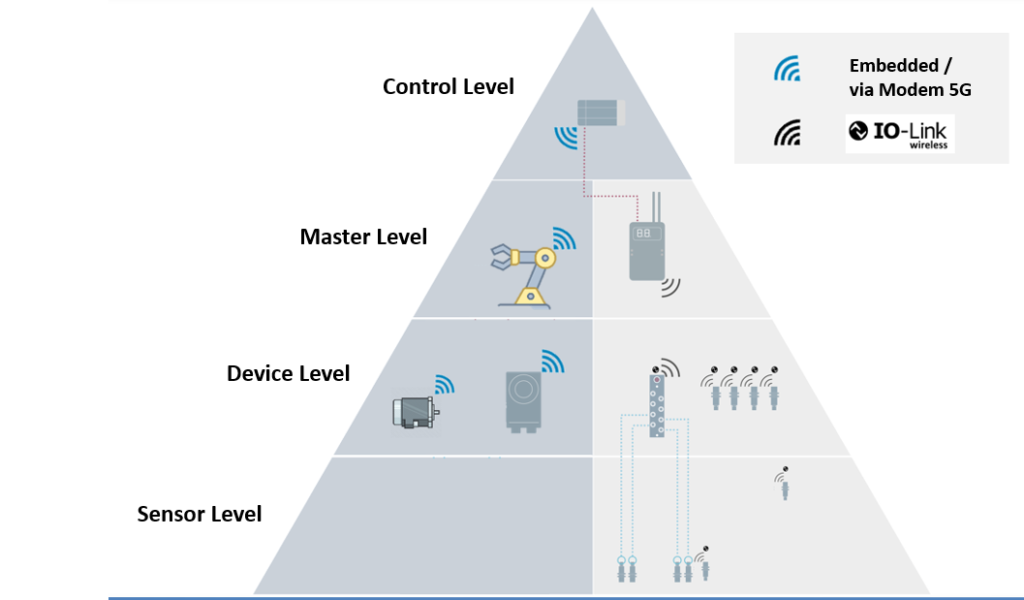

In fact, both technologies have their justifications. They cover various application areas within industrial automation technology. As a glance at the automation pyramid shows, they also address very different types of nodes in each case.

IO-Link Wireless is primarily intended for field devices in factory automation that already communicate via IO-Link. It is therefore also a solution that can be spatially limited, i.e., used selectively and scaled to transmit the signals of switching and measuring sensors, but also of simpler actuators. Process data of < 2 bytes are processed and forwarded. Since these devices are often lower cost and used in large numbers, the total cost of a system often determines the success of the new technology. In addition, the devices communicate directly with the controller via a node (IO-Link master), which makes a stable and continuous connection from master to device essential, which is also a high requirement for time-critical applications. IO-Link Wireless is based on the standardized IO-Link technology (IEC 61131-9) and, therefore, exactly meets these requirements while offering the same high communication stability (Packet Error Rate 10-9) as the wired version. In addition, it is a flexible and cost-efficient solution that can be embedded in existing infrastructure with the previously used sensors and actuators with little effort.

5G, on the other hand, was designed as a communication medium for field nodes with greater bandwidth. It is a comprehensive network infrastructure designed for a higher level of communication. For example, this technology is not designed to serve a selective application area due to the licensing costs and the investment in infrastructure. It will typically be found within the automation pyramid at the higher field level, where Ethernet-based nodes are also used, Involving, for example, communication between the controller and camera systems, servo motors, fieldbus modules, or even data transmission from robots to a gateway. These devices are typically installed in smaller quantities and, due to their complexity, are also in a different price range, which is why the additional costs for the 5G infrastructure of a complete manufacturing environment are less significant.

Since both technologies serve different use cases, they are very well suited to be used within a combined system. The different frequency bands (country-dependent for 5G) are also not expected to interfere with each other, even if they are not directly compatible. A fieldbus module could act as the hub of both technologies, communicating downward via IOLW and upward via 5G. IO-Link Wireless can, therefore, fully coexist with any 5G network. These networks do not contradict each other and will even complement each other, as 5G focuses on high-end applications with higher data throughput. A similar picture emerges for wireless applications in the consumer sector, where Wi-Fi and Bluetooth operate in coexistence with each other and definitely have their raison d’être.

Alexander Weber

Head of the Working Group “IO-Link Wireless”