In the past years, processes and business models in logistics and production have changed fundamentally, which leads to a need for technological change. Within technological change, data plays an elementary role – especially when it comes to localization. Therefore, we observe an increase in indoor localization demand in logistics and production, accompanied by an increase in RTLS (real-time location system) providers.

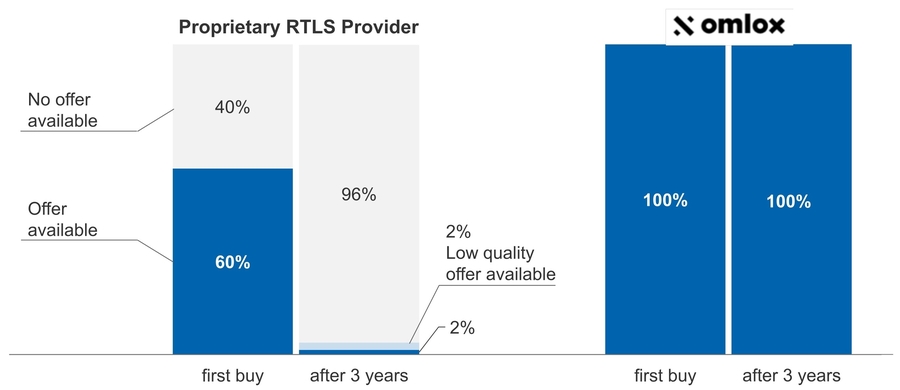

In the RTLS market, a variety of applications like movement analytics, anti-collision warning, documentation, or asset management, as well as tag types with small or large batteries, with or without display and self-locating devices, is provided. The current challenge for indoor positioning is that despite the diversity of technologies, methods, and providers available on the market, no service is offered that is equally well suited for all use cases. Around 40 percent of all customers do not find a supplier fitting for their needs, and even if they select an acceptable solution, for now, the customer’s needs might change over the years due to further digitalization, new technologies, or a change in strategy. Within three years, the strategic fit of the selected RTLS provider decreases from 40% down to 4% on average, of which only 50% will keep or exceed the level of quality needed.

This is exactly where the open location standard omlox comes in. On the one hand, omlox is able to integrate all positioning technologies (UWB, RFID, BLE, 5G, etc.). On the other hand, it allows devices from different manufacturers to participate in an open infrastructure. The interoperability of omlox enables the integration of a Lean Management approach in logistics and production. It provides fast and flexible adaptability to changes related to market challenges or new technologies in the manufacturing process, subsequent expansions, and adjustments in the RTLS-System. Those range from the navigation of employees to the implementation of AR-glasses for navigation purposes or the use of AGVs (automated guided vehicles). With an open standard as omlox, the customer can select the best module, which increases the quality of the RTLS-System by 42% and the availability of the optimal modularization up to almost 100% at any time. Furthermore, RTLS-providers do not need to offer a variety of applications and tags. Instead, they can focus on their core tasks.

Source: Scientific Research by TRUMPF Tracking Technologies GmbH in cooperation with Esslingen University of Applied Sciences (Germany).