Click on a headline or image below to learn more about a given new product.

Connection of CAN FD with PROFINET

Connection of CAN FD with PROFINET

esd electronics has extended its new PROFINET gateway family by a variant for CAN FD. It operates as a PROFINET device and connects CAN FD devices with PROFINET controllers. It works with a maximum of 1440 bytes input and output process data on the PROFINET network. On the CAN side, the gateway acts as an ordinary bus node, so that CAN FD and Classic CAN frames from any of the CAN networks can be transferred to the PROFINET side.

Miniaturized and Robust PROFINET Interface

Miniaturized and Robust PROFINET Interface

With the HARTING ix Industrial® Ethernet interface, developers can create significantly more compact devices with a more robust data interface than with previous RJ45 solutions. With the various PCB sockets, developers also have many options for device integration and a great deal of design freedom to realise the optimum solution.

Servo Drive with PROFINET for Mobile Applications

Servo Drive with PROFINET for Mobile Applications

The SIM2100 is WITTENSTEIN cyber motor’s new output variant in the cyber simco drive 2 product family. The device has IP65 protection and is designed for mobile applications in the fields of intralogistics, assembly and automation. It provides extensive safety features, for example Safe Torque Off (STO) to SIL 3 / PL e is integrated as standard. The servo drives of the cyber simco drive 2 series are offered with a PROFINET RT/IRT interface and support PROFIdrive Application Classes 1, 3, and 4.

Power Supplies with IO-Link

Power Supplies with IO-Link

Power supplies in the new DN42xx range from ifm electronic have been specifically designed for field mounting in automation applications. Three models are available, all of which provide nominal 24 DC outputs. Two models are intended for use with three-phase inputs in the range 380 to 480 V. These have four output circuits, each with two M12 L-coded connectors, and a total continuous rating of 500 W. The models differ in that one has an IO-Link interface.

2 in 1: Pressure and Temperature via IO-Link

2 in 1: Pressure and Temperature via IO-Link

The PL15 from ifm electronic can be used both as a two-wire analogue and digitally via IO-Link. In the latter case, the pressure and temperature can be read continuously, as the pressure transmitter also transmits the temperature of the medium so that a second measuring point is not necessary. The flush design provides no dead space for media to adhere to, effectively preventing clogging of the pipe. The operating hours can also be read via IO-Link.

IO-Link Photoelectric Sensor for Conveyors

IO-Link Photoelectric Sensor for Conveyors

SICK has unveiled its new Roller Sensor Bar (RSB) as an addition to its extensive portfolio of photoelectric sensors. This sensor provides the logistics and production markets a reliable solution to accommodate the ever-increasing variety of packaging shapes and sizes, and that provides a quick and easy installation experience. Obtain application diagnostic information to reduce conveyor downtime through IO-Link. IO-Link provides individual beam status information which can be used for product alignment and the skewing of objects across the conveyor bed.

Small Footprint Ejector with IO-Link

Small Footprint Ejector with IO-Link

Piab’s piCOMPACT®10X SMART multistage ejector is based on COAX technology and come with integrated controls and special functions, such as on/off valve, blow-off valve, and vacuum switch. IO-Link technology offers simplified and cheaper installation with easy set-up and less cabling. Performance and process data from sensors in, for instance, pumps can be monitored in real time using the IO-Link interface.

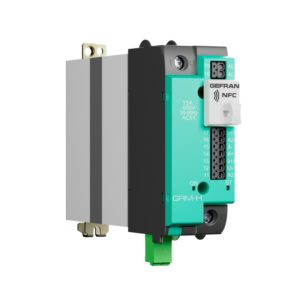

Power Controller with IO-Link

Power Controller with IO-Link

Gefran presents the GRM-H power controllers with integrated diagnostics, based on the scalable GRx platform, dedicated to the control of resistive loads in industrial heating. The solution is characterised by an ultra-compact design and by the IO-Link interface, which guarantees advanced features in an Industry 4.0 perspective. These are the first power controllers in the world to adopt this protocol which enables digital communication from the field level to the higher factory level. Therefore, in addition to cyclic process data, you can also record acyclic variables such as hours in operation, temperature peaks, energy and internal temperature, for the purpose of the machine’s efficient predictive maintenance.

Ultrasonic Flow Meter with IO-Link

Ultrasonic Flow Meter with IO-Link

Ultrasonic flow meters like the DUK from KOBOLD offer an ideal solution for non-conductive media that cannot be processed by magnetic flow technology. The DUK operates via the ultrasonic principle of transit time difference and was previously only for water and water-like media. By incorporating additional intelligent electronics with customized parameters, the DUK is now compatible for most homogeneous and Newtonian media under 68 cSt. The new model includes integral temperature measurement, IO-Link, bi-directional flow capabilities, switching and batching and transmitting functions, two configurable outputs, and a digital touch screen that rotates the display in 90 increments depending on the installation position.