Module Type Package (MTP) is an exciting technology that stands to make the integration of machines into a higher-level DCS, SCADA, or MES significantly easier and faster. It is an open standard and completely vendor-agnostic.

In the PROFINET world, we have the concept of a General Station Description (GSD) file. The GSD organizes and describes all the features, data, formatting, values, and basic capabilities of a device. It is used during the integration of the device into a controller –whether IPC, PLC, PAC, or DCS. Similarly, in the IO-Link world, we have the concept of an IO-Link Device Description (IODD) file. The IODD file too lays out all the data, units, and capabilities available from an IO-Link sensor for usage by the IO-Link master.

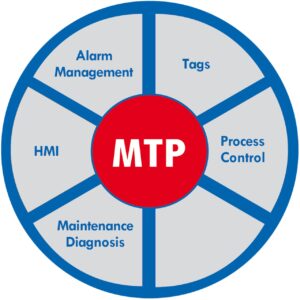

MTP is like a GSD or an IODD –but on steroids. Instead of describing a single device or sensor, MTP is utilized to describe an entire machine or subsystem. All data, operating screens, functions, and alarms of the machine are immediately available in the superordinate system. Historically, when we think about process control plants, depending on the vertical industry, we often envision monolithic systems installed and run for decades without changes. As concepts like mass customization have begun to permeate both factory automation and process control environments, the need for efficient modularization becomes critical. This is where MTP fits into the picture.

MTP is like a GSD or an IODD –but on steroids. Instead of describing a single device or sensor, MTP is utilized to describe an entire machine or subsystem. All data, operating screens, functions, and alarms of the machine are immediately available in the superordinate system. Historically, when we think about process control plants, depending on the vertical industry, we often envision monolithic systems installed and run for decades without changes. As concepts like mass customization have begun to permeate both factory automation and process control environments, the need for efficient modularization becomes critical. This is where MTP fits into the picture.

Within the scope of MTP, the software into which an MTP file is imported is defined as the Process Orchestration Layer (POL). This would be the software behind the DCS, SCADA, or MES, for example. When an MTP file is imported into the POL, offline service engineering (orchestration) is performed along with communication configuration (via OPC UA). If recipe/batch engineering is applicable, MTP utilizes the ISA 88 standard here. The next step is an Orchestration Test (“Plug”) and then to begin (“Play”). It is truly “Plug & Play”.

MTP has caught the attention of companies across industries in process control environments and hybrid process/factory environments. As demand grows for not merely interoperability, but the easy integration of machines independent of their native control system, we expect proportionate demand for MTP. The standard is an open technology that can be developed by any vendor for their products.