Three diverse application stories are covered here: The use of PROFINET network monitoring in oil & gas facilities in the Gulf region; intrinsically safe PROFINET modules for mobile pilot skids in filtration systems; and the use of hygienic IO-Link capacitive sensors in the meat processing industry.

Potential PROFINET Downtime Addressed

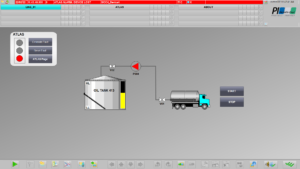

It is common on many production lines in the Gulf region, spread across different countries, to use PROFIBUS with remote monitoring on all the lines 24/7. Any malfunction is directly passed on to the control room by the network condition indicator. A brand-new oil & gas processing factory was being built up on PROFINET, so in this case a PROFINET monitoring solution had to be used. The main concern of the client was minimizing the time it takes to identify and fix any potential network issues. This was addressed from the outset –even before the plant was brought on line. The PCS7 control system from Siemens, which ASM Process Automation integrated, worked work with PROCENTEC’s Atlas remote network monitoring product to get the information in the easiest form possible into an HMI using OPC UA. Alarms were integrated from the Atlas into the PCS7 HMI allowing the operator to see and locate any potential fault in the network, should one ever occur. The next step in any potential network issue-related scenario would be calling the maintenance team to check that exact device in that exact panel and fixing the problem with the help of PROCENTEC’s Delphi tool. The Figures show the concept system of finding a potential problem in a PROFINET-based system and locating the device right away.

Mobile Pilot Filter System in Hazardous Area

BHS-Sonthofen is an owner-managed group of companies specializing in mechanical and plant engineering with headquarters in Sonthofen (Germany). Their success is based on their experts in the field of mechanical and thermal process engineering with a focus on filtering, drying, mixing, crushing and recycling. With 500 employees, three production sites and nine subsidiaries, the company has a global presence.

Application and solution

For comprehensive tests, even lasting several weeks, BHS-Sonthofen offers pilot systems as identical variants of all machines. Tests on pilot plants confirm throughput capacity, process stability and operating parameters. Tests are normally carried out by the customer in their own production environment in order to comply with existing safety regulations and to obtain direct conclusions about the production processes. Based on the results, a safe design of the production machines is possible. Pilot machines from BHS are of course also available for purchase for small-scale production.

Olaf Karl, the control technician at the subsidiary BHS Control Systems GmbH & Co. KG, and responsible for implementing the control technology for new pilot filter system, reports: “The remote I/O valve terminal from BEx-Solution gave us the necessary space savings. With the compact format it was possible to mount the box directly on the mobile pilot filter system. With the integrated valve terminal from Festo, the external tubing could be significantly reduced and simplified. Everything is already completely compatible and certified. The compact system solution simplified the installation and the documentation effort, especially for the conformity of intrinsic safety. Our analog Ex i sensors could also be connected to the BEx module. The easy integration of the I/O data via PROFINET to the PLC simplified the software effort as well.”

Based to the standardized concept of the BEx-Solution, BHS-Sonthofen will be able to set up the new filter systems more easily and quickly in the future.

Trend Hygiene 4.0: Capacitive Sensors

The high demands on plant hygiene and resilience pose challenges for many companies in the meat processing industry. This applies in particular to small components such as capacitive switches. They often have to work faultlessly at temperatures around freezing while at the same time as ensuring a sterile environment. The seal rings on the components must not corrode, even when exposed to aggressive cleaning agents. However, the increasing automation of many work processes also requires companies to rethink their solutions. Sophisticated sensor technology supports Industry 4.0 features and expands the range of switch functions. In this way, for example, companies can implement predictive maintenance or optimized processes in intralogistics. Capacitive switches are a robust, hygienic option.

For companies in the meat processing industry, strict legal requirements to guarantee end-consumer safety must be met. Until recently, mechanical switches have usually been the norm in the sector. These may be reliable, but they cannot be seamlessly installed in plants. Germs and food residues can easily accumulate, especially on mechanical and moving elements. Piezo switches, which have no moving parts, are an alternative to mechanical switches. These electrical controls are waterproof and have a slight pressure point. However, expanding their functionality for Industry 4.0 is a complex issue. Companies cannot use them to implement more complicated applications, such as dynamic functions and functions that can be changed in the process – for example via IO-Link.

Capacitive Switches Offer Robustness

That’s why so-called capacitive switches are being used with increasing frequency. They generate an electric field and measure the environment’s capacitance. If a hand approaches, the switch recognizes the change and reacts. Human conductivity is so high that even wearing gloves is not a problem. To avoid unintentional activation, they can also be set up to sense only sudden changes in capacitance. Only large changes – such as the touch of a finger – trigger a reaction. Capacitive switches can also be combined with other technologies to increase safety.

Capacitive switches have several advantages over conventional solutions: First, they can be integrated into any plant as a completely hygienic component, and do not have any mechanical elements, meaning that neither dirt particles nor germs can accumulate. Capacitive switches are also more robust than mechanical switches, making them suitable for use in meat-producing plants. Last but not least, they offer a high level of flexibility, since additional functions can be integrated via intelligent sensors or corresponding APIs.

Use Case: Capacitive Switch with Flexible Interfaces

An example of a capacitive switch is the SENSORswitch on the “Hygiene” model of the CANEO series10. The housing is rounded and made of stainless steel (1.4404). The switch itself has a long service life of over 100 million switching cycles. It also has an integrated sensor system that significantly increases the possible range of functions. All materials used meet the high requirements of the FDA (Food and Drug Administration), and are certified according to the standards of the EHEDG (European Hygienic Engineering and Design Group) due to their design. Each SENSORswitch in this series has a food-safe seal that prevents the formation of residues from cleaning substances, food, and germs. This makes the switch particularly suitable for companies with high hygiene requirements, such as slaughterhouses or butcher’s shops.

The CANEO series can be freely parameterized so that several different applications can be implemented: For example, it can be configured as a closer or opener, but different lighting scenarios are also possible using the RGB LEDs. All settings can be changed via IO-Link, either subsequently or during the process. As a result, the components can always be adapted to the individual requirements of the respective company. It can be operated ergonomically, and thus supports employees in their daily work.

The IO-Link compatibility means that the SENSORswitch can be easily used in networked Industry 4.0 environments. Here, it offers a flexible interface for numerous HMI applications (Human Machine Interface), and supports the digital transformation of machines. However, even without an IO-Link, the CANEO can still be controlled via PNP, NPN or push-pull solutions. The capacitive SENSORswitch is therefore not only suitable for smart factories with a greenfield approach, but also for brownfield factories with a mixture of intelligent systems and older models.

Conclusion

There’s no getting around it: hygiene is and will remain the be-all and end-all in the food industry. At the same time, companies have to prepare for increasing automation of their processes. This is the only way they can remain competitive in the long term. Capacitive SENSORswitches provide an efficient basis for digital transformation, and have flexible interfaces with numerous customization options. This means that meat processing plants are well prepared for the coming challenges of Industry 4.0.