New White Paper: PROFINET Optional Features

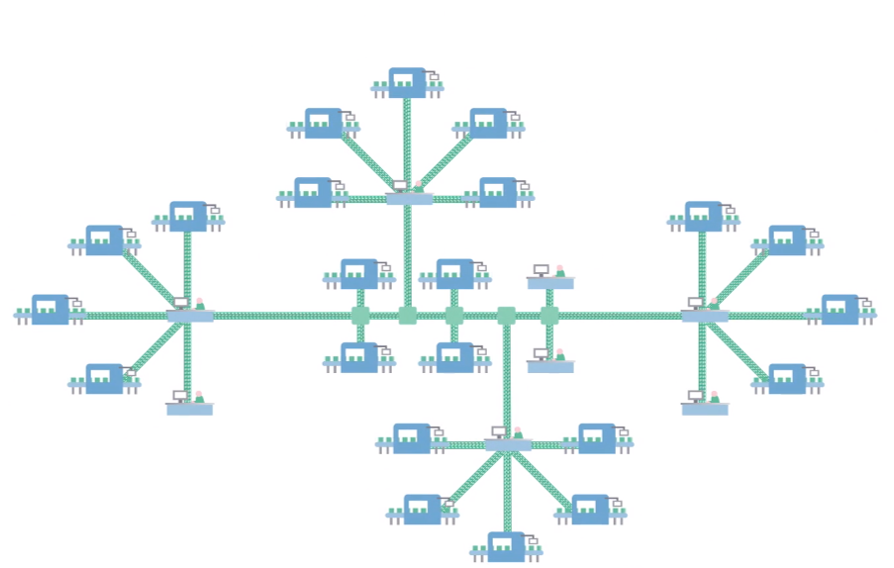

Aside from the mandatory characteristics in each PROFINET device, PI defines a list of optional features: Device Redundancy, Controller redundancy, Shared Device, I-Device, Dynamic Reconfiguration, Fast Startup, iPar Server, and much more...

![Read more about the article What are PROFINET I&M Records? [Tech Tip]](https://profinews.com/wp-content/uploads/2020/02/iM3.jpg)

![Read more about the article In with the New, Out with the Old [Tech Tip]](https://profinews.com/wp-content/uploads/2020/01/logo-combined.jpg)

![Read more about the article HMI Design: The Key to Process Efficiency [Tech Tip]](https://profinews.com/wp-content/uploads/2019/10/hmi.jpg)