For most folks jumping in to a PROFINET development project, there’s one only goal that they have in mind: exchange cyclic real-time data with a PLC. That’s the same task that every fieldbus in history has been designed around, and it comes with well-known drawbacks: devices that can only exchange data cyclically force developers to pack all sorts of data in to the real-time channel that don’t belong there.

For example, think about a drive that may need to receive a tuning parameter when it first starts up, but doesn’t need to continue receiving that parameter every cycle. Similarly, a smart camera may need to send an alarm if it detects an anomaly in a product, but it doesn’t need to send data about a non-existent anomaly every cycle, either. Products like these waste resources two ways. First, they waste storage space in the PLC by trying to pack bytes in to the cyclic data exchange that don’t belong there. Second, they create extra work for the application engineer who has to write custom code to interface with each of these devices.

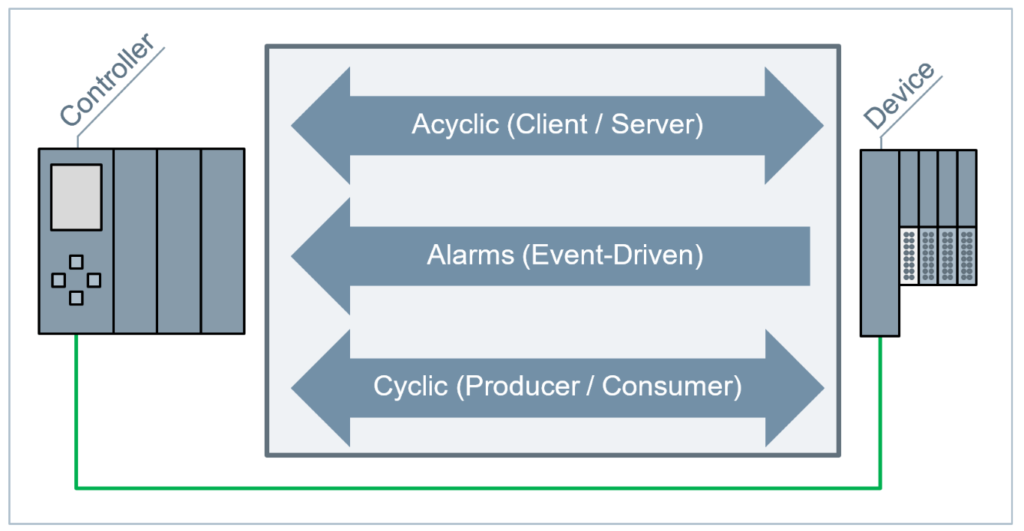

That’s where PROFINET stands out from other fieldbuses: it provides much more than just real-time communication. For instance, it provides event-driven alarms to push fault information to a Controller in a standardized, easy-to-parse format. Similarly, PROFINET also provides server-client communications via the Acyclic Records mechanism for one-off read or write operations. These features can help application engineers stretch their PLC resources further and make the most of their budgets.

By implementing these two mechanisms, developers can dramatically lower the implementation cost of their PROFINET devices. In addition to saving application development time and making more efficient hardware investments, implementing these features can give the end customer a much more robust and comprehensive system to work with. If you’re interested in implementing those or other features in to your PROFINET product, check out our developer training and drop us a line. We’ll be happy to help.

Kyle McMillan

PROFI Interface Center

Kyle provided an informal look at this situation in a guest PROFIblog post.