Customer’s challenge: Regular downtime periods were resulting in considerable loss of revenue. Some of the drives in the network were tripping intermittently and impacting production.

Utthunga service personnel had to check the PROFIBUS network in the client’s Sitarganj plant to find the details about the faults. Indu-Sol GmbH’s PROFIBUS diagnostic tools were utilized for this purpose. The PROFIBUS-INspektor® NT was installed in the main panel to analyze quality parameters of PROFIBUS communication. The tool was connected to the individual controller modules for diagnosis. Then, the network was monitored for four hours on a Siemens controller module. After capturing several error telegrams with the tool, the service personnel determined that the drives were not installed as per the PROFIBUS & PROFINET International (PI) standards.

Main Issues and Resolution

Part of the installation did not follow the one-meter rule. A cable length of less than one meter between two nodes can lead to reflections on the line and introduces errors. Also, shielding was not done properly. Finally, there was improper segmentation which let to a reduction in PROFIBUS communication voltage. A section of the PROFIBUS network had eight VFDs connected to the same segment. VFDs operate in a high voltage environment, often leading to signal deterioration. Generally, longer cables are used along with multiple segments to ensure the PROFIBUS signals are reconstructed and reduce the impact of VFDs. The signal quality was less than 2500 and it is recommended to have a signal quality of over 2500 to ensure stable and reliable PROFIBUS communication in the network.

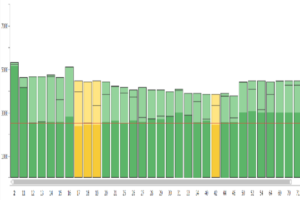

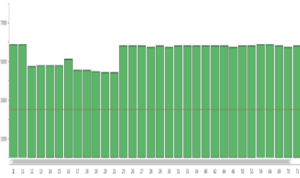

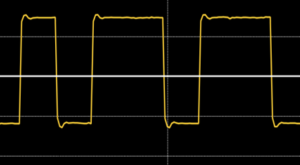

The following graphs show the traffic light of node 17 and distortion in the waveforms due to interference.

It was recommended splitting the VFDs into multiple segments using repeaters might solve the issue. Then a test was run using the repeater. The change in the network architecture enhanced the communication voltage (signal quality) of the PROFIBUS network. The figures below show the change in readings after the repeaters were installed to split the VFDs. The quality values between nodes 17, 18, 19 and 42 improved. With the help of the network experts, the client overcame the PROFIBUS network failures which were causing plant outages and utilizing significant manpower hours of troubleshooting.