From Communication to Digitalization

For some years now, we have been transitioning PI (PROFIBUS & PROFINET International) from a traditional fieldbus organization to a platform for Industry 4.0-enabling technologies. One of the recent examples was the introduction of omlox, a technology for indoor location information and services. And we are continuing to focus on promising use-cases in factories or plants to support the digital transformation of industry. One field where we could already gain experience in the past is the integration of robots through standardized profiles. In modern production lines, more and more stationary and mobile robots are being integrated as complete systems to increase the degree of automation and reduce costs. Since the production line is typically controlled by a PLC and the user programs the production line application via the PLC programming system, it is necessary to be able to uniformly control and program the complete robot systems of different manufacturers. These being integrated into the production line via the PLC programming system.

Building on Past Collaboration

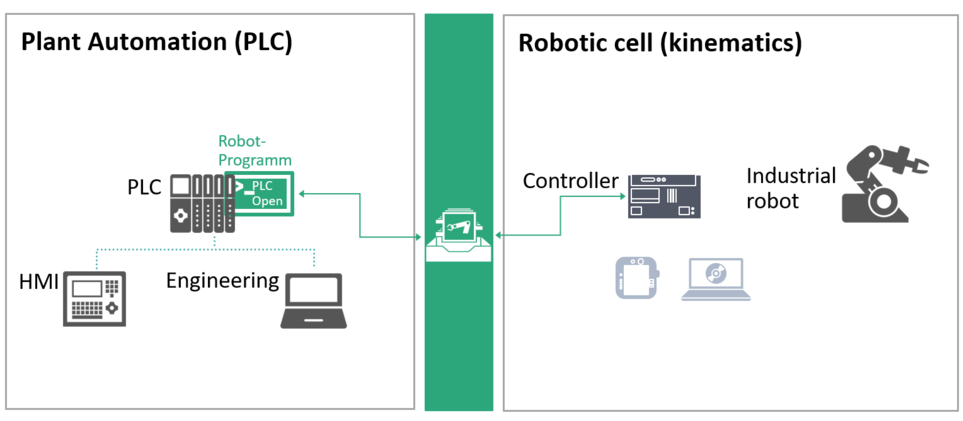

With our joint activity on OPC UA Safety and the OPC Foundation, we already had a building block towards a more seamless integration of mobile robots in a production plant. We are also addressing the use-case of PLCs controlling robots and, therefore, will define a uniform data interface between the PLC and the robot controllers to make robot programming easier and more efficient for PLC programmers and PLC suppliers. This data interface should make it possible for robot programs to be written completely in the PLC. On the one hand, this means that the PLC manufacturer only needs a single robot library based on this data interface. On the other hand, the robot manufacturer also only needs to implement a single interpreter for its robot controller. The robot functions are to be called via the data interface, and the required robot status information is to be reported back to the PLC.

With our joint activity on OPC UA Safety and the OPC Foundation, we already had a building block towards a more seamless integration of mobile robots in a production plant. We are also addressing the use-case of PLCs controlling robots and, therefore, will define a uniform data interface between the PLC and the robot controllers to make robot programming easier and more efficient for PLC programmers and PLC suppliers. This data interface should make it possible for robot programs to be written completely in the PLC. On the one hand, this means that the PLC manufacturer only needs a single robot library based on this data interface. On the other hand, the robot manufacturer also only needs to implement a single interpreter for its robot controller. The robot functions are to be called via the data interface, and the required robot status information is to be reported back to the PLC.

Increasing Ease of Use

As usual, it is PI’s goal to have a vendor-neutral interface between robots and PLCs… On both sides! With this standard, users can interconnect PLCs and robots from different brands using the same technology. It is a great step in interoperability and yet another building block for any modern factory modeled after Industry 4.0. We are continuing our path in moving the organization to a true supporter of the digital transformation occurring in our industry.

Karsten Schneider

Karsten Schneider