Welcome to 2019! In the spirit of developing networks among colleagues and among automation devices, this month’s issue focuses on PROFINET device development. Due to the rich community of solution providers and resources available to developers, adding a PROFINET interface to an automation device couldn’t be easier. It is also future-proof –many of the solutions available today are prepared for the scheduled PROFINET enhancements down the road.

Want to learn more?

Are you a developer of PROFINET devices?

Are you planning development of a PROFINET device in the near future?

We invite you to take our PROFINET Developer survey:

Click here to take a 5-minute survey

Easy Way to PROFINET Development

A variety of starter kits and evaluation boards are available for almost every implementation method. These complete sets enable a quick introduction to development activities and often contain a complete development environment, as well. Included sample programs, block diagrams, and sample circuits can be especially helpful. The development packages also include the certifiable PROFINET stack of the corresponding provider and detailed documentation.

Conformance Classes

To meet the different requirements of automation systems, three conformance classes that build upon one another are defined for PROFINET. Each class has a functional scope determined for the typical area of application. The device manufacturer must consider the required conformance class before selecting an implementation option for the PROFINET device interface, as the type of interface implementation affects the conformance class that can be achieved.

Implementation Options

Once a device manufacturer has figured out what PROFINET features they need to implement on their product, the next question is how to implement those features. There are three fundamental options:

- Chip (ASIC / FPGA)

- Module

- Software Stack

Each implementation method has its pros and cons, depending on available development capacity, company expertise, expected costs to produce the interface in volume, and the desired time to market.

Future-Proof Way to PROFINET Development

TSN is a promising technology drawing a lot of attention at the moment. TSN offers great potential for PROFINET.

TSN is a promising technology drawing a lot of attention at the moment. TSN offers great potential for PROFINET.

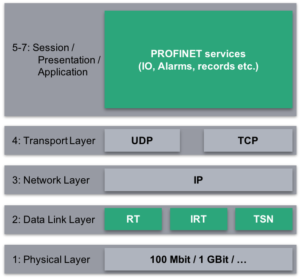

It aims to combine the wide range of IT networks with the robustness and determinism of automation networks. In short: hard real-time via standard IT networks. But this doesn’t signal a revolution for PROFINET. Rather, it represents a visionary architecture upon which PROFINET is building.

TSN offers PROFINET a new Layer 2 in the ISO/OSI model. Nothing more, nothing less. It thus corresponds to today’s RT and IRT technologies. And this makes it clear that TSN will not simply replace RT or IRT in the coming years. It’s an additional option with a number of benefits. Today’s manufacturers that are providing solutions with RT and IRT will be able to continue providing them in the future. Users employing RT or IRT in operating their systems can be sure that they are using a sustainable technology.

TSN offers the possibility to achieve this also with standard chip-sets because TSN is based on open standards and many semiconductor vendors will support these standards. Everything else about PROFINET remains unchanged – especially such services as diagnostics, configuration, alarms, etc. This will make it easy for users and device manufacturers alike to use TSN in the future. They can build on existing knowledge and continue using the applications they have developed.

Furthermore, some technology providers today make note of the fact that their solutions are forward compatible to the PROFINET@TSN spec, scheduled for release at Hannover Fair 2019. So, implementing PROFINET today means future-proof connectivity for tomorrow.

To learn more, check out the other articles in this issue that focus on PROFINET development, and thank you for reading this issue of PROFINEWS!