As already predicted in 2020, the success of Industrial Ethernet continues, and with it the rise of the manufacturer-independent Ethernet interface PROFINET. PROFINET is fast, transparent and future-oriented, making it an excellent fit for Dunkermotoren. With PROFINET, the drive technology manufacturer presents its real strengths – the integration of the complete electronics into the motor housing. Dunkermotoren thus offers a super-compact overall solution with synchronous communication and eliminates the need for costly gateways.

Commissioning is much simplified compared to previous solutions: the drives can easily be integrated into the operating environment. Thanks to the drive profile PROFIdrive with application classes 1 to 4, which is also completely integrated in the motor, no tedious tuning of individual parameters or programming of sequences are necessary. Thus, synchronous operation of several axes is no problem. But what about PROFINET systems without PROFIdrive? Here, Dunkermotoren ensures fast commissioning with its own Quickstart commands. Each of those combine several commands and ensure a more structured and user-friendly sequence program.

Another advantage of PROFINET is that the highly synchronous process data is not affected despite the simultaneous transmission of huge amounts of status and time data, which in turn enables permanent monitoring and analysis of all components in the system. PROFINET’s OPC UA capability allows the data to be transported in a secure manner and to be made semantically machine-readable. This in turn opens the gates to the IIoT and Industry 4.0, allowing, for example, a digital twin to be compared with the real application at any time. With its own brand nexofox, Dunkermotoren not only offers the drives themselves, but also provides support in the field of IIoT with a holistic range of solutions for the use and networking of its smart motors. Anyone who wants to see PROFINET & Dunkermotoren can convince themselves by looking at the trade fair model from SIEMENS at LogiMAT in Stuttgart. With the help of Dunkermotoren with integrated PROFINET interface, a SIMIT simulation with a digital twin simplified the commissioning of the system and identified and corrected potential weaknesses even before the real setup.

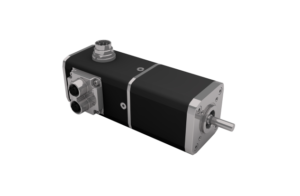

More specifically, Dunkermotoren offers completely integrated solutions with the BG 45, 66, 75 and 95 dPro PN series. Alternatively, all drives of the BG series can also be used in the dCore version with an external controller, such as the BGE 5510 dPro PN. If, due to the topology or special safety functions such as SLS or SSM, a Siemens controller is appropriate, SIMATIC MICRO-DRIVE controllers can be used just as easily, for which Dunkermotoren offers a perfectly matching drive portfolio.

In addition to the communication interface and the complete output stage such encoders and controllers including dynamic motor monitoring, motors from Dunkermotoren also include the appropriate mechanical components. Customers receive a complete drive unit consisting of motor, gearbox, brake and linear cylinder – customized and from one single source. Connecting, integrating, configuring and producing is very simple using the “Drive Assistant 5” commissioning tool. Drive Assistant 5 establishes contact with the motor via the Ethernet connection. Final details and special step-by-step instructions are explained in the commissioning instructions “Let’s connect”. The nexofox team advises or assists in the use and networking of the motors and beyond.

Thanks to the PROFINET certification, Dunkermotoren also guarantees smooth functionality. This ensures an error-free operation marking troubleshooting completely unnecessary over the entire service life. Worry-free from the beginning to the end.

Dunkermotoren has held its line with PROFINET and has set new standards: The combination of PROFINET and PROFIdrive with application classes 1 to 4 completely integrated into the drive – and in all sizes from the small BG 45 to the powerful BG 95.